The PSA Process : a high technology perfectly known by NOVAIR Medical

The oxygen generator is based on a patented implementation of the Pressure Swing Adsorption (PSA) which uses ambient air as raw material.

Ambient air contains 21% oxygen, 78% nitrogen, 0.9% argon and 0.1% rare gases. The PSA process is a static separation of air gases via a specific molecular sieve designed to adsorb nitrogen under pressure, to produce oxygen-enriched air composed of 93% oxygen and above.

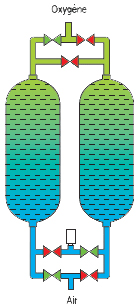

The oxygen generator is mainly composed by 2 separation vessels filled with molecular sieve adsorbers (zeolites), one complete pneumatic system (valves, filters, pressure regulator...) monitored by an automatic device, and an oxygen tank.

PSA process 5 main stages

- Compressed air (78% nitrogen, 21% oxygen, < 1% argon) is filtered, degreased and dried and the production pressure is automatically regulated.

- Air passes through the molecular sieves where nitrogen is adsorbed by the zeolite, increasing oxygen concentration up to 95%.

- Out of the molecular sieve, the oxygen produced is sent through the buffer tank via a mutifunction block. Nitrogen is released via a silent escape and forced back outside.

- Part of the oxygen produced is used to help the nitrogen desorption of one vessel while the other ensures oxygen production (and vice versa).

- An automatic and pneumatic vessels balance system ensure a continuous oxygen flow.